How To Buy Better Quality Cattle Panels With Gate

DB Fencing is the third supplier of Anping, China for corral panels and livestock yards, including cattle panels, cattle gate, ramp, sliding gate, Adjustable Cattle Loading Ramp With Winch, cattle headrail, cattle crush, may gate, race bow, round hay feeder, and related accessories for Australia and New Zealand market.

All corral yard products are designed, tested, manufactured by ourselves, which are Australia standard.

For Further Information and requirements please contact: info@metalfencetech.com

DB Fencing has been in this cattle yards field since 2017, distribute all through Australia. We design these cattle-yard products for Australian farmers, supplying many of the features and benefits. And we also get more and more good feedback from Australian customers.

You must make it clear how is the cattle yards working before buying

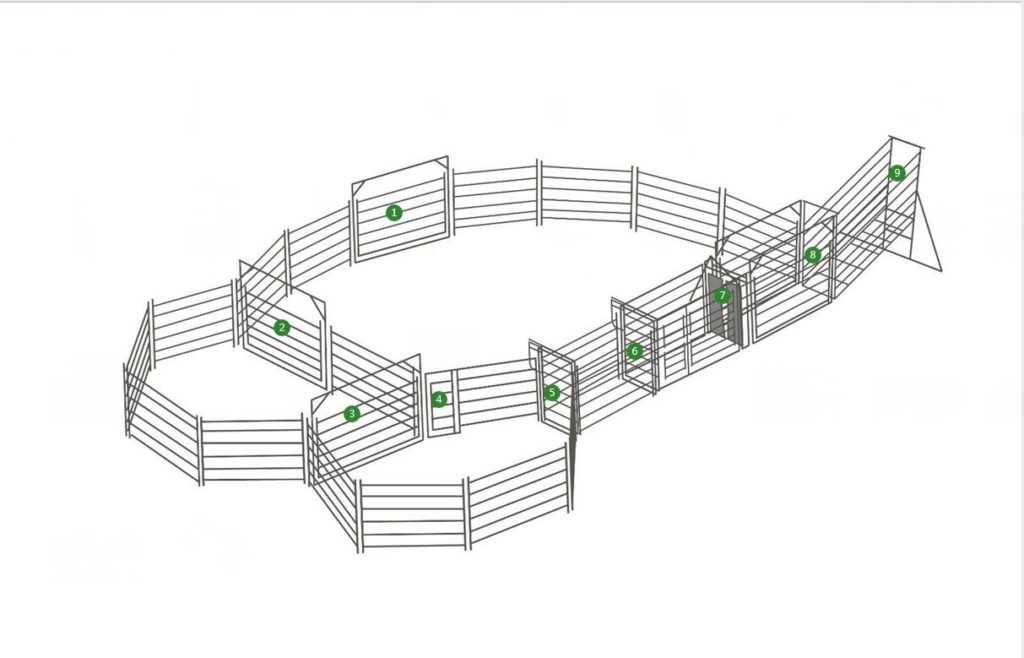

Let us explain the design of the working yard with 40-50 head cattle.

Cows and calves should never be tightly forced or in the race together (From NSS Yard)

| Holding Yards | Forcing Yards | |

100 – 300 kg | 1.3m² | 0.6m² |

300 – 500 kg | 1.4m² | 1.0m² |

| Over 500 kg | 1.6m² | 1.2m² |

| Cows & Calves | 2.2m² | 2.2m² |

① Confirm a set of yards you like can be moved the cattle around and work. What we’ll do is we’ll take the cattle around the back of the yards into the working area by the cattle gate. Also, you can have a cattle-free zone (Laneway) for the safety of farmers and children.

② Open the second cattle gate (2.3 x 2.1m Width or larger) to put enough cattle (5-10) go through and been into the second working area 1/4 yard, then close the gate with a slam latch or put a chain on it.

③ Open the third cattle gate to make some cattle (5 cattle) in the pen. After close the gate, the man can go out of the area from the manway gate. The man gate 40×80 should be wide enough to stop the cattle come in to have accidents.

④ Push them around up to the race very easily. Please notice there is no need to push cows up a race in the area. Just go out of the fourth gate and onto the grip strut grating to handle the cattle come into the race. The race should be in line to prevent cattle jamming

⑤ Open the sliding gate with the roller bearing, and the cattle will flow into the race easily.

⑥ Heavy-duty cattle crush working easily. Whatever your cattle size, you can adjust the crush width to suit with a hand shank. Have your head bail to operate the cattle head. Two-way draft out of the crush.

⑦ The good quality of cattle goes onto the truck by loading ramp.

⑧ Watch out: When you are in the same working area with cattle, please remember the safety, you should always stand at the end of the gate, also keep a stick in your hand.

⑨ Cattle yards should be a closed circle around the animals flowing.

Necessary Quality Consideration Before Import Cattle Panels From China

DB Fencing manufactures super and sturdy cattle panels for your yards. We always follow the yard development of Australia to design and sell the right panels at affordable prices.

Providing the conveniences, saving the cost, reduce livestock stress, supplying better quality and after-sales services for Australia small cattle yard designs and large commercial cattle yards are our further aim.

How Many Cattle Panels With Gates would you need – 2.2M, 2.5M, 3.2M, 4.0M

The number of cattle panels required for a portable yard depends on the size of the yard.

How to compare the better quality of cattle panels

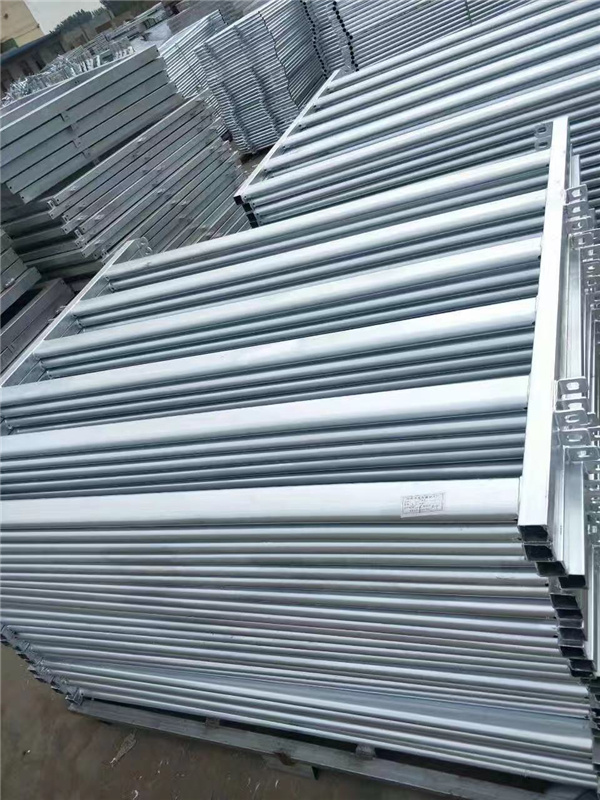

Firstly, There are lightweight and heavy-duty cattle panels for your choices. One is 3060mm horizontal oval rails and the other 40x80 heavy-duty rails. Also, you can choose pre galvanized finishes to save costs, hot-dipped galvanized for your super cattle yards or powder-coated black color cattle panels. All panels are fully welded to provide enough strength and sturdiness.

Pre- Galvanised cattle panels

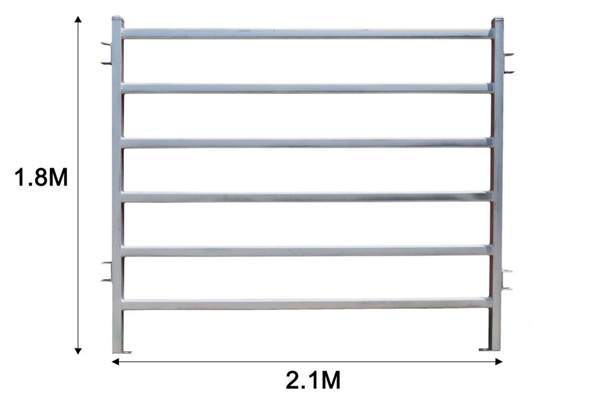

The frame size 1800mm(H) x 2100mm (W), vertical frame post 50 x 50 x 1.6mm Galvanized RHS, horizontal rails 30 x 60mm 6 x 1.6mm Galvanised Oval Rail for lightweight panels (not get their head through it), 42x115x2.0mm (stronger and adult cattle cannot get their head between the rails), 5 rails, and 40 x 80mm 6 x 1.6mm for heavy-duty cattle panels. All products are manufactured from the high-quality pre-galvanized tube, fully welded for every corner joint, then a smooth surface, finally paints with rust protection to last longer. These kinds of panels are economical and popular in the Australian market.

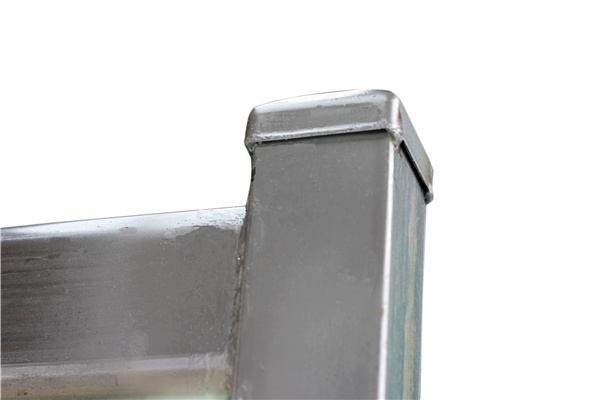

Also, the rainhat on the top post is a tower model, which flows the rain quickly to protect the panels.

There are 2 U-type lugs on the left side, 2 L-type lugs on the right side, and 2 bottom plates inside.

Hot Dipped Galvanised cattle panels

The frame size is 1800mm(H) x 2100mm (W), vertical frame post 50 x 50 x 1.6mm steel material RHS, horizontal rails 40 x 70mm 6 x 1.6mm raw material Oval Rail for heavy-duty cattle panels. All products are manufactured from the high-quality raw steel tube, fully welded for every corner joint, then a smooth surface, finally hot-dipped galvanised more than 58 microns to guarantee 10-15 years. These kinds of panels is premium in Australian commercial cattle yards.

Please note: Because it is a hot-dipped galvanised process, the horizontal rails should be punched in the zinc-flow hole (10x15mm) to finish the galvanised.

Use the rubbers on the joining connectives around the lug hole to reduce the noises of two cattle panels when high wind or cattle hit a slam.

Powder Coated Cattle Panels

Whatever lightweight cattle panels or heavy-duty, they both can be powder-coated black color.

The frame size 1800mm(H) x 2100mm (W), vertical frame post 50 x 50 x 1.6mm Galvanized RHS, horizontal rails 30 x 60mm 6 x 1.6mm Galvanised Oval Rail for lightweight panels, and 40 x 80mm 6 x 1.6mm for heavy-duty cattle panels. All products are manufactured from the high-quality pre-galvanised tube, fully welded for every corner joint, then a smooth surface, finally powder coated. This kind of panels are competitive prices and does the same anti-corrosion ability as the hot-dipped galvanized cattle panels.

Cattle Gate

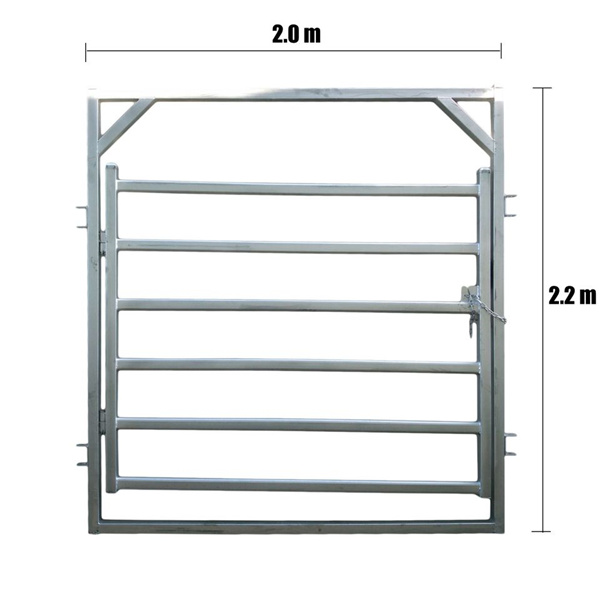

Cattle gate in a frame outside lengths: 2.3M, 2.6M, 3.3M, 4.1M, 5.2M, available in 6 rails, also 7 and 8 rails for sheep/goat/cattle combination yards.

Also, the cattle gate can be hot-dipped galvanized, pre-galvanized, and powder coated.

Cattle Gates Features

- Mitre cut bracing for support top frame tube, 360 degrees welded for strength quality, gate no bending

- Bottom steel plate with thick pins connected into the ground to solid

- Open 90 degree, 180 degree can be your choices

- 32 x 10mm Slam catch hot dipped galvanised to keep the door closed

- You can put a permanent post 2.9M H to make a temporary yard very solid and permanent.

- Cattle Gates need to fold back 180 degrees, open inside 110 degrees, so avoid the injury and break the gate when cattle cross.

- Slam catch with the backing plate stop the cattle escape from the gate. If more cattle heads, you should choose a wider gate to prevent the cattle bruising.

- Ground pins can be necessary.

For Further Information and requirements please contact: info@metalfencetech.com