One Importance To Buy Temporary Fence System

One Importance To Buy Temporary Fence System

Temporary fencing is a security and portable wire mesh fence with Australian characteristics, widely used in major public events, sports, concerts, festivals, gatherings, and more…

As a local supplier of temporary fencing, the quality of temporary fence imported is so important and also related to the long-term cooperation between its end users. The second is the price, that is, the best, reasonable and most competitive price.

When you need to purchase a lot of temporary fencing for sale, you will google the keyword “temporary fencing prices”, or “temporary fence panels for sale”, then you will find a lot of Australian temporary construction fence for sale suppliers, but pls find the temporary fencing supplies in China, because price best.

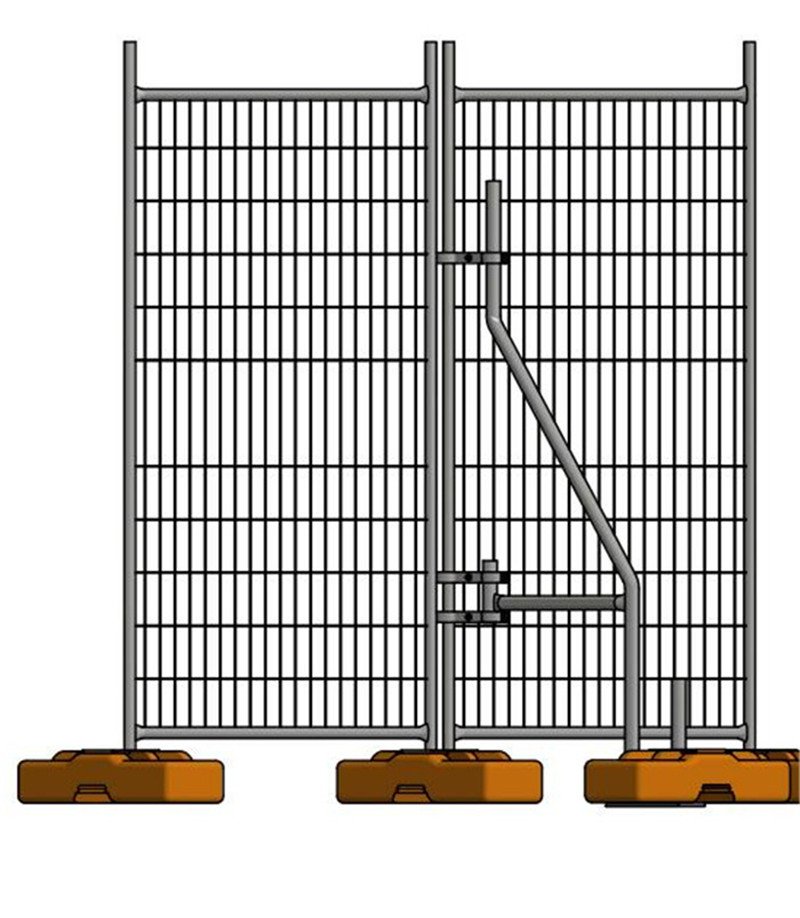

First, let’s analyze the quality factor. It is well known that the temporary fence system includes a temporary fence panel, plastic base, steel clamp, as well as bracing, shade cloth, temp fence gate, and so on.

Temporary Fencing Panels Two Finishing Ways

Temporary fence standard specification in Australia is AS4687-2007 standard, the only specifications 2.4 x 2.1 m, 4.0 mm wire diameter, 60 x 150mm (c/c) mesh spacing, 32 x 2. 0 mm frame tubing, hot dipped galvanized 42 Microns.

As everybody knows, Anping county of China is the “Wire Mesh of Hometown” in the world, The most competitive price and best quality are from Anping county, as a variety of wire mesh fence, the best choice to buy temporary fence is Anping county. The development of wire mesh here has a history of more than 100 years. While a temporary fence history of more than 20 years.

During these 20 years, there are no less than 50 x 40ft containers of temporary fence exported to the Australian market every day. However, Technology is improving, and temporary fence manufacturing technology has changed a lot. But this change is a cheap, shoddy business type. A temporary fence is an infilled wire mesh welded together with a frame tube. Every point of the mesh should be welded to achieve a strong, wind-resistant effect. However, some profit-driven Anping suppliers have maximized their benefits by reducing the cost of welding points, so that the temporary fence exported to Australia cannot meet the standard, its service life is shortened, and it must be replaced every few months, causing great trouble and economic cost to the end-users. The temporary fence panels produced by Anping DB Metal Fencing Co., Ltd have been manufactured strictly according to the real requirements of customers and their quality has been guaranteed. Therefore, they have won the trust and long-term orders from many Australian customers. Another most important quality factor is galvanized finishing for corrosion resistance.

Hot Dipped Galvanized Temporary Fencing Panel Process

Nowadays, temporary fence panel has developed to be another new surface finishing way on the basis of hot-dipped galvanized, that is, painting galvanized on galvanized pipe, which is shown as welding of galvanized pipe and galvanized wire (with 14 microns of zinc), spraying anti-rust paint on welding points, which is greatly reduced in quality. Now, this kind of surface treatment is almost the standard, but in the end, it is the user who is unfortunate, although the price is cheap but only used for a short time and then has to change a new product.

1. Pre-Galvanized Temp Fencing Panels Welding

2. Pre-Galvanized Temp Fencing Panels Painting Silver Color

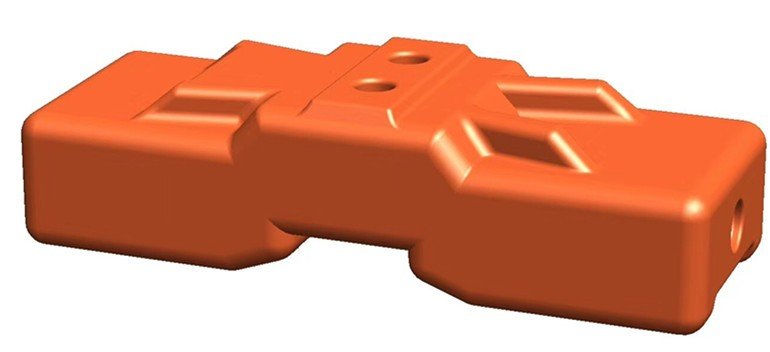

2. Temporary Fence Base/Block/Feet Quality Notice

In Anping, there are only a few plastic bases produced by ourselves, about 2-3 companies. DB Fencing is one of them. Because it is not produced by Anping itself, the sellers of many other companies in Anping did not understand the quality control and technical principles of the base, and sold the second grade HDPE material and faded color plastic base to the customers, which seriously affected the customers’ economic interests.

Let me explain to you: There are two different types of plastic bases for injection molding and blow molding. The size of the injection molding base is 560 x240x130mm, and the blow molding base is 610x230x150mm. Because the two kinds of the base are both mold production, so the size of each product is basically the same.

1. Blow Moulding Plastic Base

2. Injection Moulding Plastic Base

The difference is in the quality control of fading, which is that many manufacturers sell the fading products last two or three months to Australian customers because they did not know the composition of the base. UV is a very important part of the base composition. High-quality anti-UV formula, UV absorbent 2002, UV UV-p, UV absorbent UV-531 as well BHT2, 6-di-buty1-4-methyl phenol yellow UV; Temporary fence feet material: Adopt bright and pure master color granules, high – density polyethylene No. 5502. The temp fence feet have good mechanical properties, The tensile strength is more than 50 mph, The tensile strength is 500 kg/cm. The Impact to hold more than 50 j/m, bending elasticity of 24000 kg/cm, the load winding temperature more than 100 ℃, hardness, Perfect aging. Temporary fence Base weight can be customized according to customer requirements for weight 0.9,1.0,1.1, 1.5kg to 1.2kg, and a variety of 1.5kg.

Temporary fence feet dimensions are mounted 32/38/40/42/48/50mm long tubes (various diameter details). According to the requirements of customers filling cement and iron tray packaging, Iron tray packaging in line with the Australian export standard without inspection, without fumigation, can make the goods clear customs smoothly, solve the worries of export enterprises.

In all, when Australian customers choose temporary fencing again, please discuss with the supplier carefully.