Description

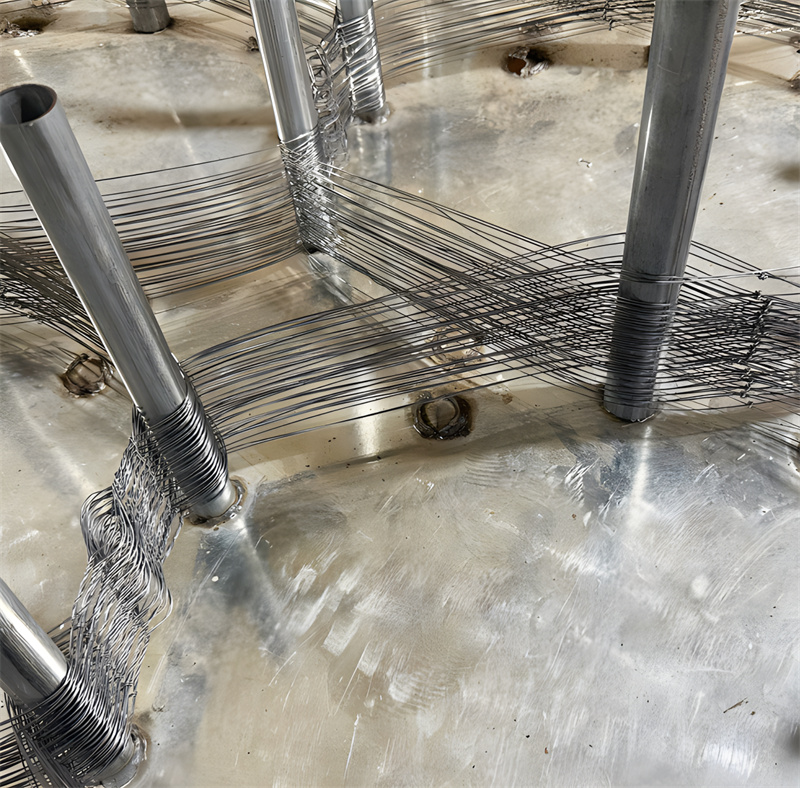

Tank Tracks Mesh is a specialized defensive wire mesh designed to halt or delay the movement of tanks and other armored vehicles, making it a critical component in modern battlefield defense. Made from high-strength, corrosion-resistant wire, this mesh provides formidable protection in various terrains. It is particularly effective in creating barriers that can disrupt enemy advances, offering the defender crucial time to mount counter-attacks.

Style and Specifications:

- Material: High-strength, corrosion-resistant steel wire.

- Unfolded Dimensions: 10x10x1.4 meters.

- Wire Diameters: Available in 0.5mm, 0.6mm, 0.8mm, and 0.9mm options.

- Folded Dimensions: 1.2×0.6×0.8 meters.

- Package Weight (without rings and pegs): 24 kg.

- Complete Set Includes: 40 pieces of connecting rings (0.8mm annealing wire) and metal posts (25 cm long).

Design and Form:

- Form Classification:

- Corrugated Wire Mesh: This version is 10 meters long, 4 meters wide, and 1.4 meters high, suitable for laying on the ground or in grass.

- Wheeled Wire Mesh: Composed of 10-20 cylindrical wire meshes, this version offers enhanced stability and protective capabilities.

- Material Characteristics: The mesh is made from high-strength, corrosion-resistant iron wire, ensuring durability and performance in harsh battlefield environments. The surface may also be treated with barbs or cutting edges to increase its destructive impact on enemy vehicles.

Features:

- High Durability: Crafted from corrosion-resistant steel wire, the mesh can endure severe battlefield conditions without degrading.

- Strong Defensive Capabilities: The mesh physically prevents or delays the movement of tanks by wrapping around their tracks, eventually halting their advance entirely.

- Concealed Installation: The mesh is designed to be unobtrusive, blending into the surrounding terrain to create an effective yet hidden barrier.

- Versatile Use: Ideal for rapid deployment in critical areas such as highways, bridges, and mountain passes, where it can disrupt enemy advances and provide time for defensive maneuvers.

Application:

Tank Tracks Mesh is primarily used for creating obstacles that impede the movement of tanks and armored vehicles. It can be quickly deployed in key areas to block or redirect enemy forces, buying time for defensive repositioning or reinforcement. The mesh can also be combined with other fortifications to establish a comprehensive, multi-layered defense system.

Installation:

-

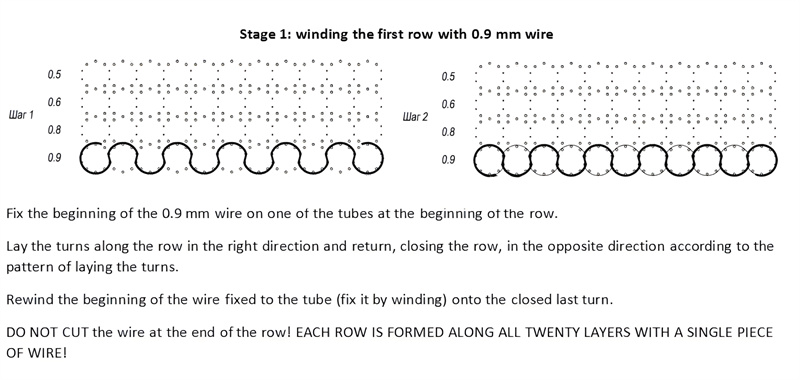

Stage 1: Winding the First Row with 0.9 mm Wire

- Secure the beginning of the 0.9 mm wire to one of the tubes at the start of the row.

- Lay the wire turns along the row in the correct direction, then return, closing the row in the opposite direction.

- Rewind the wire at the end of the row without cutting, ensuring continuous coverage across all twenty layers.

-

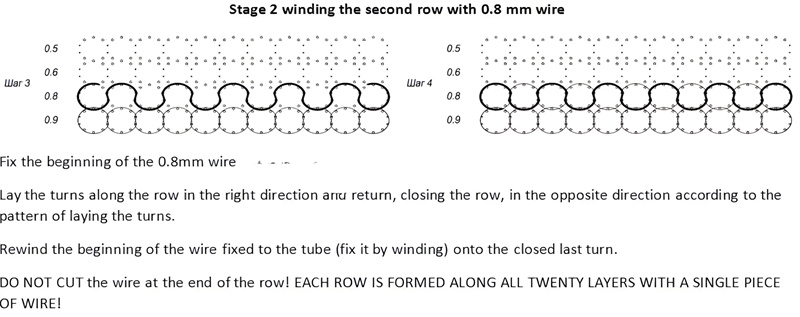

Stage 2: Winding the Second Row with 0.8 mm Wire

- Fix the beginning of the 0.8 mm wire and follow the same process as the first stage.

- Ensure the wire is wound tightly and securely at the end of the row.

-

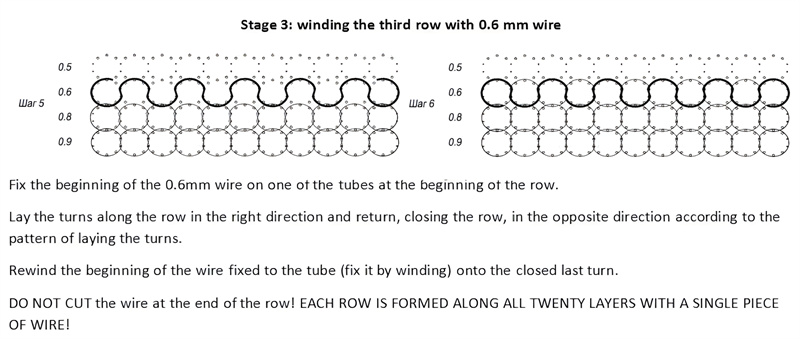

Stage 3: Winding the Third Row with 0.6 mm Wire

- Repeat the winding process with 0.6 mm wire, maintaining the same pattern and tension as in the previous stages.

-

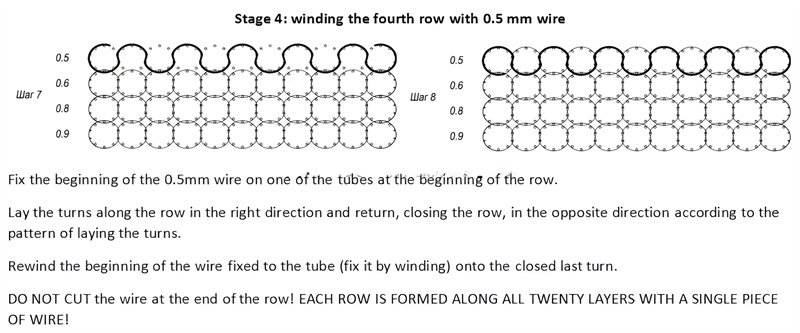

Stage 4: Winding the Fourth Row with 0.5 mm Wire

- Complete the final winding with 0.5 mm wire, ensuring the entire mesh is covered uniformly and securely.

Advantages of DB Fencing Tank Tracks Mesh:

- Indestructibility: The high-strength, corrosion-resistant wire ensures the mesh remains intact and effective even under intense pressure and harsh conditions.

- Concealment: The mesh’s unobtrusive design allows it to blend into its surroundings, making it difficult for enemy forces to detect and navigate around.

- Cost-Effectiveness: Despite its advanced defensive capabilities, the mesh offers a low-cost solution for protecting critical areas.

- Versatility: Suitable for a wide range of applications, from military fortifications to border security, the Tank Tracks Mesh is an adaptable and reliable defense tool.

Usage Scenarios:

- Military Fortifications: Deploy the mesh on battlefields to stop or slow down advancing tanks and armored vehicles.

- Border Security: Use the mesh as a barrier to prevent unauthorized crossings and protect national borders.

- Infrastructure Protection: Install the mesh on highways, bridges, and other strategic points to safeguard against potential threats.

- Multi-Layered Defense Systems: Combine the mesh with other defensive measures to create a comprehensive security network.

DB Fencing’s Tank Tracks Mesh is an essential tool in any defense strategy, providing robust protection against armored threats and ensuring the security of key areas. Whether used in military, border, or infrastructure applications, this mesh delivers unparalleled performance and peace of mind.

Frank Zhang –

Q: What role does the advanced anti-tank mesh play in the ongoing war in Ukraine?

A: The advanced anti-tank mesh serves as a vital component in enhancing the survivability of armored vehicles against anti-tank weapons during the war in Ukraine. This innovative technology helps to mitigate the impact of missiles and anti-tank guided missiles, making it an essential asset for ground forces.

Q: What is an anti-tank wire mesh barrier?

A: An anti-tank wire mesh barrier is a robust defense structure designed to impede the movement of armored vehicles, such as tanks, on the battlefield. It is typically made from high-quality galvanized steel or stainless steel wire mesh, which ensures durability and effectiveness in military applications.

Q: How does wire mesh work as an obstacle for armored vehicles?

A: Wire mesh functions as an obstacle by creating a physical barrier that hinders the mobility of armored vehicles. The design of the anti-tank wire mesh, often welded or woven into rings, effectively disrupts the tank’s movement, making it a vital component in battlefield defense.

Q: What materials are commonly used in the construction of anti-tank wire mesh?

A: The most common materials for constructing anti-tank wire mesh barriers include galvanized steel and stainless steel. These materials are chosen for their strength, corrosion resistance, and longevity, ensuring that the barriers remain effective over time.

Q: Can anti-tank wire mesh barriers be customized for specific needs?

A: Yes, many wire mesh manufacturers offer customization options. Depending on the intended use and battlefield conditions, you can specify dimensions, materials, and additional features like concertina barbed wire or razor barbed wire for enhanced security.

Q: What is the difference between anti-tank wire mesh and barbed wire?

A: While both serve as barriers, anti-tank wire mesh is designed to withstand the impact of armored vehicles and create a significant obstacle, whereas barbed wire primarily deters personnel and animals. Combining both can create an effective multi-layered defense system.

Q: How can I purchase high-quality anti-tank wire mesh online?

A: You can easily find wire mesh products online from reputable suppliers in China and other countries. Look for manufacturers that provide hassle-free transactions, competitive pricing, and reliable shipping options to ensure you receive quality anti-tank wire mesh.

Q: What are the benefits of using welded gabions in conjunction with anti-tank wire mesh?

A: Welded gabions provide stability and weight to the barrier system. When filled with sand or other materials, they enhance the effectiveness of anti-tank wire mesh by creating a robust defensive bastion that can withstand impacts from armored vehicles.

Q: Are there options for low visibility anti-tank barriers?

A: Yes, there are options available for inconspicuous obstacle wire woven into rings or invisible obstacle fences that blend into the environment. These designs are particularly useful for stealth operations where maintaining a low profile is essential.

Q: How do I ensure that my wire mesh product meets ISO standards?

A: To ensure your wire mesh product meets ISO standards, purchase from a certified wire mesh manufacturer that adheres to international quality standards. Check for certifications and quality assurance processes in place to guarantee the reliability of the anti-tank wire mesh.