Discover the world of molded fiberglass FRP grating panels and why they are the ideal solution for a wide variety of applications. This comprehensive guide will help you understand the benefits, manufacturing process, and how to select the right grating for your needs.

What Is Molded Fiberglass FRP Grating?

Molded fiberglass FRP grating is a type of grating made from fiberglass reinforced plastic. This molded grating is known for its exceptional strength, corrosion resistance, and lightweight properties.

Kluczowe cechy:

- Corrosion Resistance: Ideal for harsh environments.

- High Strength-to-Weight Ratio: Strong yet lightweight.

- Versatility: Suitable for various applications, including floors, platforms, and walkways.

How Is Molded Grating Manufactured?

The manufacturing process of molded fiberglass grating involves a specialized molding technique.

Kroki:

- Mold Preparation: A mold with the desired mesh pattern is prepared.

- Fiberglass Placement: Fiberglass rovings are layered in the mold.

- Resin Application: The mold is filled with a thermosetting resin system.

- Curing: Heat and pressure cure the resin, forming a solid grating panel.

- Demolding: The finished płyta is removed and trimmed to the required rozmiar.

This process creates a one-piece construction that offers uniform strength and stiffness.

Benefits of FRP Grating

Choosing FRP grating provides numerous advantages over traditional materials like steel or aluminum.

High Load Capacity

Nasz grating is engineered to handle high load capacities, making it suitable for heavy-duty applications.

Corrosion Resistance

The use of quality resin ensures excellent chemical and corrosion resistance, extending the lifespan of the grating in harsh environments.

Lightweight and Durable

Despite its strength, fiberglass grating is lightweight, reducing installation costs and making it easier to handle.

Understanding Resin Systems in Grating

The resin system is crucial in determining the performance of the FRP grating.

Types of Resin Systems

- Isophthalic Polyester Resin: Offers a balance of cost and chemical resistance.

- Vinyl Ester Resin: Provides excellent chemical and corrosion resistance.

- Phenolic Resin: Ideal for fire resistance and high-temperature applications.

Selecting the right resin system ensures the grating meets the specific requirements of your application.

Exploring Different Panel Sizes and Mesh Patterns

We offer grating panels in various sizes I mesh patterns to suit different applications.

Rozmiary paneli

- Standard panel sizes range from 3’ x 10’ to 4’ x 12’.

- Custom sizes are available upon special order.

Mesh Patterns

- Square Mesh: Provides multidirectional strength.

- Rectangular Mesh: Offers higher stiffness in one direction.

Can FRP Grating Handle High Load Capacities?

Absolutely! Our FRP grating is designed with a high strength-to-weight ratio, allowing it to support substantial loads.

Factors Contributing to High Load Capacity

- Resin System: Enhances stiffness and durability.

- Fiberglass Reinforcement: Provides structural strength.

- Projekt: Optimized for load distribution.

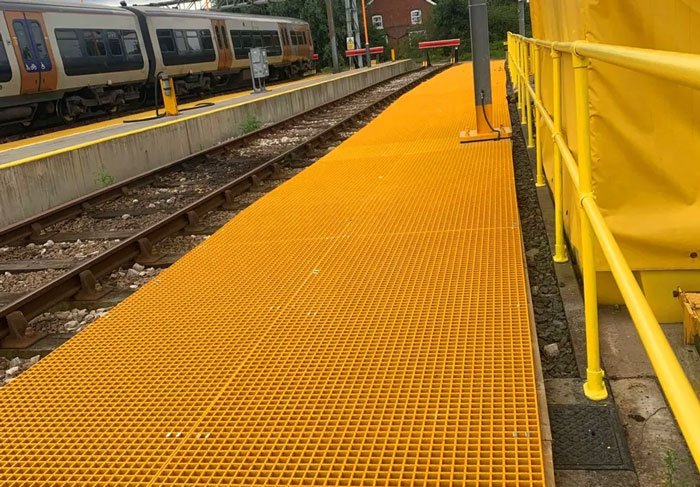

This makes it suitable for industrial flooring, platforms, and walkways.

Surface Options: Which One Suits Your Application?

Choosing the right surface is essential for safety and performance.

Surface Types

- Gritted Surface: Offers superior slip resistance.

- Concave Surface: Provides basic anti-slip properties.

- Covered Surface: Ideal for areas where a solid floor is required.

Consider the environment and usage when selecting a surface option.

Chemical Resistance Guide for FRP Grating

Nasz FRP grating provides excellent resistance to a range of chemicals.

Factors Affecting Chemical Resistance

- Resin System: Different resins resist different chemicals.

- Concentration and Temperature: Higher levels may require specialized resins.

Refer to our Chemical Resistance Guide for detailed information.

Applications of Molded Fiberglass Grating

Molded fiberglass grating is versatile and can be used in numerous settings.

Common Applications

- Marine and Coastal Environments: Resistant to saltwater corrosion.

- Industrial Flooring: Durable under heavy loads.

- Public Buildings and Infrastructure: Safe and non-conductive flooring.

- Transportation: Platforms and walkways in railway and airport facilities.

How to Select the Right FRP Grating Panel

Selecting the appropriate grating involves considering several factors.

Key Considerations

- Application Requirements: Load, span, and environmental conditions.

- Resin Selection: Based on chemical exposure and temperature.

- Surface Type: Depending on slip resistance needs.

- Panel Size and Thickness: To meet structural requirements.

Our experts can assist you in choosing the right solution.

Skontaktuj się z nami to discuss your specific needs.

Często zadawane pytania

1. What is the difference between molded and pultruded grating?

Molded grating is created in a single-piece molding process, offering multidirectional strength, while pultruded grating is made by assembling pultruded profiles, providing high strength in one direction.

2. Can FRP grating be customized?

Yes, we offer custom sizes, shapes, and colors to meet your specific applications.

3. How does FRP grating compare to steel grating?

FRP grating is lighter, corrosion-resistant, and non-conductive, offering several advantages over steel, especially in corrosive environments.

4. Is FRP grating suitable for outdoor use?

Absolutely! Its corrosion resistance makes it ideal for marine, coastal, and other outdoor environments.

5. What colors are available?

Standard colors include yellow and dark gray, but other colors are available upon request.

6. How is FRP grating installed?

Installation is straightforward due to its lightweight nature and can be done using standard clips and hardware.

Najważniejsze wnioski

- FRP grating offers a combination of strength, durability, and corrosion resistance.

- Zrozumienie resin system and surface options helps in selecting the right product.

- Suitable for a wide variety of applications across different industries.

- Custom solutions are available to meet specific needs.

- Easy installation and low maintenance make it a cost-effective choice.

For more information or to request a quote, Skontaktuj się z nami. We’re here to help you find the perfect FRP grating solution for your project.

Related Products:

- FRP Grating Price Australia

- Pultrudowana krata FRP

- Kratka zabezpieczająca Grip Strut

- Heavy Duty Temporary Fence

- Industrial Guardrail Systems

- Chain Link Fence Solutions

Our FRP grating is the ideal choice for industries ranging from mining and heavy industries to marine and coastal environments. With its high load capacity and corrosion resistance, it’s designed to meet the demands of various applications.

Ready to upgrade your infrastructure with high-quality FRP grating?

Contact us today to discuss your project requirements and discover how our solutions can benefit you.