Ensuring safety in industrial and commercial environments is crucial. Grip strut safety grating is a steel product designed to provide slip-resistant surfaces, enhancing safety underfoot. In this article, I’ll share why grip strut is the ideal solution for your facility and how it can benefit you.

What Is Grip Strut Safety Grating?

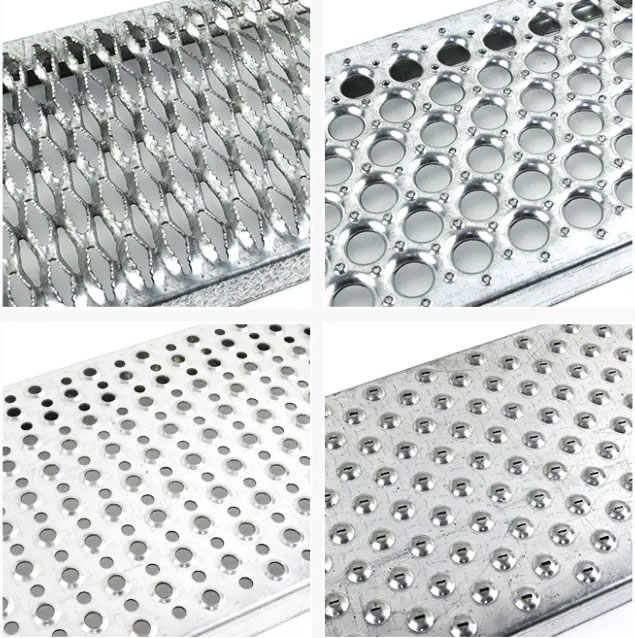

Grip strut safety grating is a type of metal plank designed for safety underfoot. Made from steel oder aluminum, it features a unique diamond-shaped construction that provides excellent slip resistance. This design ensures safety in environments where mud, ice, snow, grease, or oil might create slippery or hazardous conditions.

Why Choose Steel for Safety Grating?

Choosing steel for your safety grating offers several benefits:

- Haltbarkeit: Steel provides high load capacity and long life, making it ideal for heavy-duty applications.

- Stärke: It boasts a high strength-to-weight performance, ensuring stability without excessive weight.

- Vielseitigkeit: Steel grip strut is suitable for various environments, including industrial and commercial areas.

How Does Grip Strut Provide Slip Resistance?

Der grip strut design features:

- Serrated Surface: Offers maximum traction in all directions.

- Open Diamond Pattern: Allows for drainage of fluids like water or detergents, preventing buildup.

- Selbstreinigend: The design ensures that debris like mud or snow doesn’t accumulate, maintaining a safe walking surface.

Applications in Industrial and Commercial Areas

Grip strut safety grating is ideally suited for:

- Walkways and Catwalks: Provides a secure walking surface in industrial settings.

- Stair Treads: Enhances safety on stairs, reducing slip hazards.

- Work Platforms: Offers stability for equipment and personnel.

- Bridges and Ramps: Ensures safe footing in areas prone to slippery conditions.

Unser Advanced Machine Fencing Systems incorporate grip strut grating to enhance safety in industrial environments.

Understanding Gauge and Thickness

Gauge Und thickness are critical factors:

- Gauge: Refers to the metal’s thickness. A lower gauge number means a thicker material.

- Dicke: Determines the grating’s strength and load-bearing capacity.

Selecting the appropriate gauge ensures the grating can handle the expected load and environmental conditions.

Ideal Walking Surfaces for Grip Strut

Grip strut is perfect for walking and working surfaces where mud, snow, ice, oil, or detergents might create hazardous conditions. Its benefits include:

- Slip Resistance: The serrated tread provides excellent traction.

- Drainage: The open design allows liquids to pass through, preventing puddles.

- Haltbarkeit: Withstands harsh environments without compromising safety.

Comparing Grip Strut to Other Metal Gratings

When comparing grip strut to alternatives like bar grating oder lightweight metal grating:

| Besonderheit | Grip Strut | Bar Grating |

|---|---|---|

| Slip Resistance | Superior | Mäßig |

| Load Capacity | Hoch | Variable |

| Drainage | Exzellent | Good |

| Gewicht | Lightweight | Schwerer |

| Installation | Easy | Requires more effort |

Grip strut’s unique design makes it a standout choice for safety-focused applications.

Installation Tips for Grip Strut Grating

To ensure safety and longevity:

- Measure Accurately: Determine the required width and length.

- Choose the Right Material: Select steel oder aluminum based on the environment.

- Secure Properly: Use appropriate fasteners for secure installation.

- Follow Guidelines: Adhere to manufacturer instructions for optimal results.

For temporary installations, our Temporäre Zaunelemente offer secure and convenient solutions.

Maintenance for Longevity

Maintaining your grip strut grating ensures long-term performance:

- Regelmäßige Reinigung: Remove debris to maintain the slip-resistant surface.

- Inspektion: Check for signs of wear or damage periodically.

- Protective Coatings: Consider galvanization to prevent corrosion.

Proper maintenance keeps your grating in top condition, providing safety for years.

FAQs About Grip Strut Safety Grating

1. What materials are available for grip strut grating?

Grip strut grating is typically made from steel oder aluminum, each offering durability and strength.

2. Can grip strut be used outdoors?

Yes, grip strut is designed for both indoor and outdoor use, withstanding various environmental conditions.

3. How does grip strut improve safety?

Its serrated surface and open design provide superior slip resistance and drainage, reducing slip hazards.

4. Is grip strut easy to install?

Absolutely. Its lightweight nature and design make installation straightforward, saving time and effort.

5. Where can I purchase grip strut safety grating?

You can explore our Griffstreben-Sicherheitsgitter for high-quality options.

Zusammenfassung

- Grip strut safety grating enhances safety underfoot with its unique design.

- Made from durable steel oder aluminum, it’s ideal for various applications.

- Provides excellent slip resistance in all directions.

- Einfache Installation and low maintenance make it a cost-effective solution.

- Suitable for environments where slip hazards are a concern.

Looking to improve safety in your facility? Explore our Griffstreben-Sicherheitsgitter products or Contact Us for expert advice.

Additional Resources

- Temporäre Werbetafeln: Secure your site with our Temporäre Werbetafeln.

- FRP-Gitter: For corrosion-resistant options, check out our FRP-Gitter.

- V-Maschenzaun: Enhance perimeter security with our V-Maschenzaun.

- Maschendrahtzaunplatten: Versatile solutions available here.

- Advanced Machine Fencing Systems: Learn more about our safety solutions.

Die wichtigsten Erkenntnisse

- Sicherheit zuerst: Grip strut grating provides essential slip resistance.

- Durable Materials: Made from steel or aluminum for longevity.

- Vielseitige Einsatzmöglichkeiten: Ideal for industrial and commercial use.

- Einfache Installation: Lightweight and user-friendly.

- Geringer Wartungsaufwand: Simple upkeep ensures long-term performance.

Ready to enhance safety in your facility? Reach out to us today, and let’s find the perfect solution together.