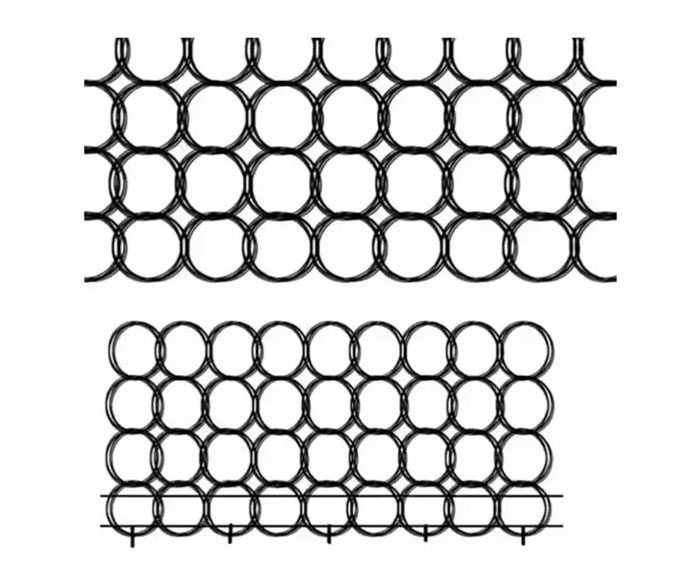

In today’s evolving landscape of strategic defense, anti-tank track wrapping wire mesh has emerged as a critical component in modern battlefield protection. This comprehensive guide explores how these sophisticated defense systems are manufactured and deployed to form an impenetrable barrier against armored threats.

What Makes Anti-Tank Track Wrapping Wire Mesh Essential for Modern Defense?

The advancement of armored vehicle technology has necessitated innovative defensive solutions. Tank track wrapping wire mesh represents a specialized defense system designed to physically prevent or delay the movement and attack of tanks. These systems are particularly effective because they target the tracked movement mechanism of tanks, making them a vital component in any comprehensive defense strategy.

Understanding the Manufacturing Process and Quality Standards

Manufacturing anti-tank wire mesh requires strict quality control and specialized expertise. The process involves:

- Advanced weaving techniques for optimal strength

- Corrosion-resistant iron wire treatment

- Rigorous testing protocols

- Quality assurance at every production stage

Modern factories producing high quality anti-tank barriers must maintain exceptional standards to ensure each wire mesh designed specifically meets battlefield requirements.

How Does Tank Track Wrapping Wire Mesh Function in Combat?

When deployed on the battlefield, these defense systems serve multiple purposes:

- Hinder the advance and maneuver of violators

- Provide units and reserves with favorable conditions for blocking

- Create delay zones in critical areas

- Form effective obstacles against armored vehicle movements

Each tank wire mesh is usually woven into fences to form an impenetrable barrier, typically spanning 10 meters long and 4 meters wide for optimal coverage.

Key Features of Modern Anti-Tank Barrier Systems

The latest anti-tank barriers incorporate several innovative features:

- Enhanced durability for harsh battlefield conditions

- Strategic deployment capabilities

- Stronger stability and protection

- Advanced corrosion resistance

- Rapid installation mechanisms

Strategic Applications and Deployment Scenarios

Anti-tank track wrapping wire mesh finds applications in various defensive scenarios:

- Perimeter security for strategic installations

- Temporary defensive positions

- Permanent fortification zones

- Emergency response barriers

Installation and Maintenance Best Practices

Proper installation is crucial for tank barrier nets to function effectively:

- Site preparation and assessment

- Strategic placement planning

- Secure anchoring methods

- Regular maintenance protocols

- Performance monitoring

Anti-Tank Mesh vs Traditional Defense Systems

Compared to conventional defensive measures, tank wire mesh offers several advantages:

- Cost-effective deployment

- Minimal maintenance requirements

- Enhanced mobility resistance

- Superior durability

- Hassle-free transaction and installation

Environmental Impact and Sustainability Considerations

Modern anti-tank wire manufacturing emphasizes:

- Eco-friendly production methods

- Sustainable material sourcing

- Minimal environmental footprint

- Recyclable components

- Reduced waste generation

Future Trends in Anti-Tank Defense Technology

The evolution of tank track wrapping obstacle wire continues with:

- Advanced material development

- Smart deployment systems

- Enhanced durability features

- Improved installation methods

- Integration with digital defense networks

FAQs About Anti-Tank Track Wrapping Wire Mesh

How long does anti-tank mesh typically last in field conditions? Under normal conditions, properly maintained anti-tank mesh can remain effective for 10-15 years, depending on environmental factors and usage intensity.

What makes these systems different from standard barrier systems? Anti-tank track wrapping wire mesh is specifically engineered to target the movement mechanism of tanks, making it more effective than standard barriers for armored vehicle defense.

Can these systems be rapidly deployed in emergency situations? Yes, modern systems are designed for both permanent installation and rapid emergency deployment, typically requiring minimal specialized equipment.

How does weather affect the performance of anti-tank mesh? Modern anti-tank mesh is engineered with corrosion-resistant iron wire to withstand various weather conditions while maintaining optimal performance.

Die wichtigsten Erkenntnisse

- Anti-tank track wrapping wire mesh provides essential battlefield defense capabilities

- Modern manufacturing ensures superior quality and durability

- Strategic deployment enhances overall defense effectiveness

- Regular maintenance ensures long-term performance

- Advanced features offer advantages over traditional systems

Learn more about our temporary fencing solutions Explore our security barrier options Discover our metal fencing solutions Check out our barrier systems View our fence panel options