In modern defense strategies, Wire Mesh Tank Obstacles play a critical role in impeding the movement of enemy tanks and armored vehicles. These obstacles are not only used in military fortifications but also in various security applications where robust barriers are required. However, purchasing the right Wire Mesh Tank Obstacle involves understanding several key factors, including material specifications, installation procedures, and their effectiveness in different environments. In this comprehensive guide, I’ll share with you everything you need to know before purchasing Wire Mesh Tank Obstacles.

Understanding Wire Mesh Tank Obstacles

What Are Wire Mesh Tank Obstacles?

Wire Mesh Tank Obstacles, often referred to as anti-tank nets, are specially designed defensive barriers made from high-strength, corrosion-resistant steel wire. These obstacles are engineered to physically prevent or delay the movement of tanks and armored vehicles by entangling their tracks or wheels, thus halting their advance and buying critical time for defensive forces.

البنية والتكوين

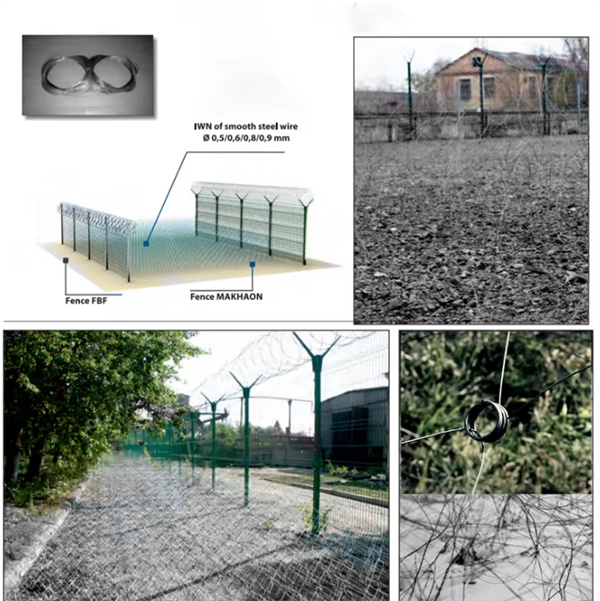

These obstacles are typically composed of wire with diameters ranging from 0.5mm to 0.9mm, woven into a mesh structure that can be deployed in various configurations. The mesh is designed to wrap around the tracks or wheels of an advancing tank, causing significant friction and eventually immobilizing the vehicle. The most common forms of Wire Mesh Tank Obstacles include large sheets of mesh that can be laid on the ground or cylindrical shapes that are deployed in layers to increase stability and effectiveness.

Applications of Wire Mesh Tank Obstacles

Wire Mesh Tank Obstacles are widely used in several defensive scenarios:

- التحصينات العسكرية: Primarily used to stop or slow down enemy armored vehicles, these obstacles are deployed in strategic locations such as border crossings, mountain passes, and access roads to prevent or delay enemy advances.

- Infrastructure Security: These obstacles are also employed to protect critical infrastructure by creating barriers that hinder unauthorized vehicular access.

- Temporary Roadblocks: In situations where rapid deployment is necessary, Wire Mesh Tank Obstacles can be quickly set up to create effective roadblocks on highways or at strategic points during military operations.

اعتبارات رئيسية قبل الشراء

1. الاستخدام المقصود

Before purchasing Wire Mesh Tank Obstacles, it’s important to define the intended use. Are you looking to fortify a military base, protect a sensitive border area, or create temporary roadblocks during an operation? The specific application will determine the type and size of the obstacle you need. For example, obstacles designed for long-term military use will have different requirements than those needed for temporary deployments in civilian areas.

2. جودة المواد

The effectiveness of Wire Mesh Tank Obstacles largely depends on the quality of the materials used. Ensure that the wire mesh is made from high-grade steel that is corrosion-resistant and capable of withstanding harsh environmental conditions. The wire diameter, typically between 0.5mm and 0.9mm, should be chosen based on the level of resistance required. For example, thicker wire offers greater durability and resistance to mechanical stress, making it more suitable for heavy-duty applications.

3. Deployment and Installation

Ease of deployment is a crucial factor, especially in emergency situations where time is of the essence. Wire Mesh Tank Obstacles can be deployed manually or with the aid of machinery, depending on their size and configuration. The obstacles should be easy to install, requiring minimal manpower while ensuring maximum effectiveness. It’s also important to consider whether the obstacles need to be permanent or temporary, as this will affect the installation process and the choice of materials.

4. Cost-Effectiveness

While Wire Mesh Tank Obstacles are generally cost-effective, the total cost includes more than just the purchase price. Installation, maintenance, and potential reuse should also be considered. Opt for obstacles that offer long-term durability and can be reused in multiple locations, thereby maximizing your investment. Additionally, purchasing from a reliable supplier that offers competitive pricing without compromising on quality is essential.

5. Environmental Impact

Consider the environmental impact of deploying Wire Mesh Tank Obstacles, especially in sensitive areas. While these obstacles are designed for durability, their installation can disrupt local ecosystems if not managed properly. Choosing materials that are environmentally friendly and ensuring that the obstacles can be removed and reused can help mitigate negative impacts.

المواصفات الفنية

1. الأبعاد والتكوينات

Wire Mesh Tank Obstacles come in various sizes and configurations to suit different defensive needs. Here are some typical specifications:

- Unfolded Dimensions: 10x10x1.4 meters

- قطر السلك: Available in 0.5mm, 0.6mm, 0.8mm, and 0.9mm

- Number of Garlands: 20 pieces per unit

- الأبعاد المطوية: 1.2×0.6×0.8 meters

- Package Weight: Approximately 24kg without rings and pegs; 40kg complete with all components.

These specifications ensure that the obstacles are compact when stored but expansive and effective when deployed. The wire’s high tensile strength, ranging between 500-800 MPa, ensures that the mesh can withstand significant mechanical stress.

2. مواصفات المواد

- سلك فولاذي: Made from high-carbon steel, which offers high tensile strength and excellent corrosion resistance.

- المعالجة السطحية: The wire is typically zinc-coated to prevent rust and extend the obstacle’s lifespan, even in harsh environmental conditions.

- Garland Count: Each unit consists of multiple garlands (rings of wire) that form a complex mesh, which increases the obstacle’s ability to entangle and immobilize vehicles.

نصائح التثبيت والصيانة

1. إعداد الموقع

Proper site preparation is essential for the successful deployment of Wire Mesh Tank Obstacles. The area where the obstacle will be installed should be cleared of debris, and the ground should be as level as possible. This ensures that the obstacle will be stable and effective in stopping vehicles.

2. Deploying the Obstacle

The deployment process varies depending on the type of obstacle. For example, large mesh sheets may require several people or machinery to spread and secure, while cylindrical obstacles can be rolled into position and anchored with stakes. It’s important to ensure that the thickest diameter wire is placed at the bottom, as this provides the most stability and resistance to the force of an advancing vehicle.

3. Securing the Mesh

After the obstacle is deployed, it must be securely fastened to the ground. This is typically done using metal stakes or anchors placed at regular intervals (every 1-2 meters). The top of the mesh can also be secured to raise the barrier to its full height, ensuring maximum effectiveness.

4. الصيانة الدورية

To maintain the effectiveness of Wire Mesh Tank Obstacles, regular inspections are necessary. Look for signs of wear and tear, especially after severe weather conditions or military engagements. Any damaged sections should be repaired or replaced immediately to ensure the obstacle remains fully operational.

Why Wire Mesh Tank Obstacles Are the Best Choice

1. فعالية مثبتة

Wire Mesh Tank Obstacles have been tested in some of the most challenging environments worldwide. Their proven ability to stop or delay armored vehicles makes them an essential component of modern defensive strategies. Whether used in military operations or for protecting critical infrastructure, these obstacles provide a reliable means of defense.

2. براعة

These obstacles are highly versatile and can be used in various applications, from military fortifications to temporary roadblocks and border security. Their modular design allows them to be adapted to different terrains and defensive requirements, making them a valuable tool in any defensive arsenal.

3. النشر السريع

In emergency situations, the ability to quickly deploy a defensive barrier can make all the difference. Wire Mesh Tank Obstacles can be rapidly installed, providing immediate protection where it’s needed most. This quick deployment capability is particularly valuable in military operations, where timing is crucial.

4. المتانة على المدى الطويل

Made from high-quality, corrosion-resistant materials, Wire Mesh Tank Obstacles are built to last. They can withstand harsh environmental conditions and repeated use, making them a cost-effective solution for long-term defense needs.

Why Choose Chinese Suppliers for Wire Mesh Tank Obstacles?

In recent years, the growth of B2B small and medium enterprises (SMEs) in China has provided a wide array of options for sourcing products like Wire Mesh Tank Obstacles. However, many of these SMEs lack the professional export experience required to consistently deliver high-quality products. These companies often operate with minimal foundations, offering little understanding of product service concepts or the importance of long-term customer relationships. As a result, the quality of their products can be unreliable, particularly when they focus solely on one-time sales rather than building enduring business partnerships.

For businesses new to importing from China, the risk of encountering an inexperienced or unprofessional supplier is significant, especially without the guidance of a reliable purchasing agent. Choosing a subpar supplier can lead to receiving products that do not meet required standards, resulting in additional costs, delays, and potentially jeopardizing your project.

لماذا تختار سياج DB؟

In this landscape, DB Fencing distinguishes itself as a reliable and professional supplier, offering several key advantages that set it apart from the competition:

1. Expertise and Experience

DB Fencing brings over a decade of experience in exporting Wire Mesh Tank Obstacles and related products. This extensive experience means they understand the stringent standards and requirements essential for both military and civilian applications. Their deep industry knowledge ensures that they consistently deliver products that meet or exceed customer expectations.

2. Quality Assurance

Quality is the cornerstone of DB Fencing’s operations. Each product undergoes rigorous inspection at every stage of production, from raw material procurement to cutting, welding, galvanization, and final packaging. This meticulous attention to detail minimizes the defect rate to nearly zero, ensuring that customers receive products that are fully compliant with their specifications.

3. أسعار تنافسية

DB Fencing’s long-standing relationships with upstream raw material suppliers allow them to negotiate prices approximately 10% below market rates. This cost-saving is passed on to customers, offering prices typically 15% cheaper than those found on major platforms like Alibaba. Despite competitive pricing, DB Fencing does not compromise on product quality, providing exceptional value for money.

4. Professional Communication

DB Fencing’s sales team is proficient in English, eliminating language barriers and significantly improving communication efficiency. Customers can expect clear and prompt responses to inquiries, detailed quotations, and solutions to any questions or concerns that arise during the purchasing process.

5. Trust and Reliability

DB Fencing has built a solid reputation for reliability and trustworthiness. The company emphasizes transparent communication, ensuring that any issues encountered during production are promptly addressed and resolved in collaboration with the customer. This approach fosters strong, lasting relationships with clients, encouraging repeat business and long-term partnerships.

6. Comprehensive Service

From initial inquiry to final delivery, DB Fencing offers a full suite of services to support their customers. This includes one-by-one product inspection, the provision of comprehensive inspection reports, and high-quality lifestyle photography to ensure that customers receive exactly what they ordered.

كيفية الشراء من DB Fencing

1. Inquiry and Communication

Start by sending an inquiry to DB Fencing’s professional sales team. They will respond promptly with detailed quotations and answers to any questions you may have about the Wire Mesh Tank Obstacles.

2. Order Processing

Once the order is placed, DB Fencing follows the contract closely to ensure that production is carried out to the highest standards. Any issues that arise during production are communicated transparently to the customer.

3. Inspection and Quality Control

Every product is inspected individually, and a detailed inspection report is provided. This thorough process ensures that any defects are caught and rectified before shipment, minimizing the risk of receiving substandard products.

4. Shipping and Delivery

DB Fencing ensures that all products are securely packaged and shipped according to the agreed schedule. Customers can expect timely delivery and continuous updates on the status of their order.

Choosing the right supplier for Wire Mesh Tank Obstacles is crucial to the success of your project. With DB Fencing, you are assured of high-quality products, competitive pricing, and professional service. Their commitment to excellence, backed by years of experience, makes them a trustworthy partner for all your defense and security needs.